|

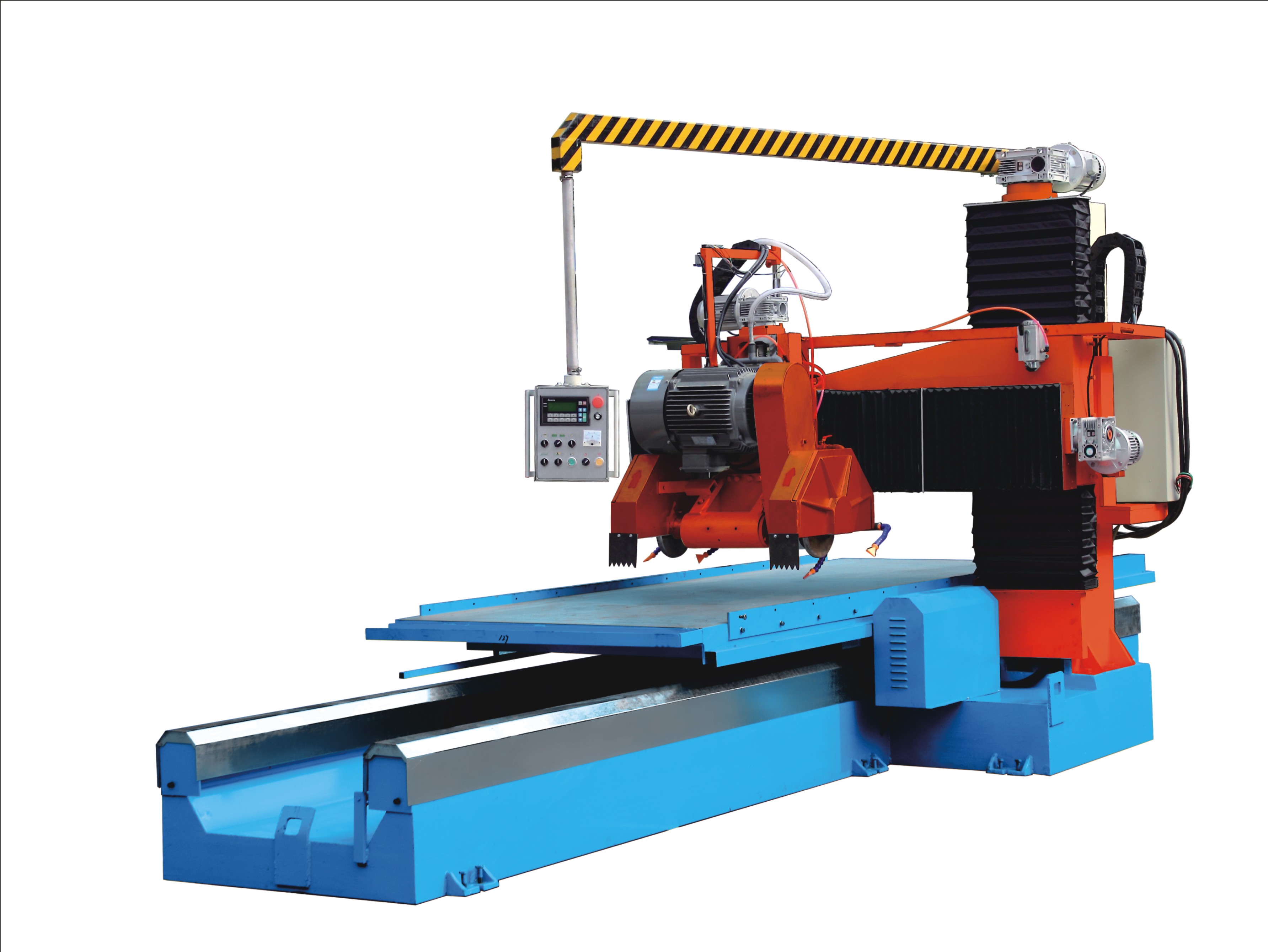

BCZ-500 Computerized Profiling Cutter Machine

infomation: Industrial Class ARM7 Micro-processing Chips;

HF output; can control micro-stepping drivers and servo drivers; Two-axis linkage; can extended into four-axis linkage; 32M storage space for user’s soft-wares; Dynamic graphics, with 7 inch LCD display The control & programming soft-wares are complete, easy to operate, visual and WYSIWYG; Use the international standard general instruction format, and add a lot of extended instructions to simply the programming; 8-channel photoelectric isolation inputs and 8-channel photoelectric isolation outputs; Adopt the U-disk storage procedures and timely update the soft-wares; Four relays are provided outside the system: ① cutting-saw switch, ② cooling-pump switch, ③ mine-truck forward rotation, ④ mine-truck reverse rotation; Cabinet Dimension: (300×202×96) mm Working Temperature: 0 °C ~ +40 °C; storage temperature: - 40 °C ~ + 60 °C. 1.2 System Main Functions & Characteristics High reliability; has the ability to resist the high-voltage interference, lightning strike and surge current; The system has the functions of automatic type & procedure programming, parameter setting, system diagnosis, cutting-machine conversion, etc. Perfect system diagnosis: input/output port checking Use international standard general instruction format, including: Point Control, Linear Cutting, Circular Cutting (clockwise & counterclockwise), transfer, calling-up subroutine, fixed circulation, returning initial point, initial-point setting, absolute / gain mode, S, T, M functions; Tool compensation, reverse gap compensation |

| Model | BCZ-500 | BCZ-500 | |

| Max. Cutting Length | mm | 3200 | 3200 |

| Max. Cutting Width(2 pieces/once) | mm | 2*600 | 4*200 |

| Max. Cutting Thickness | mm | 300 | 300 |

| Blade Diameter | mm | Ф350~Ф600 | Ф350~Ф600 |

| Main Motor Power | kW | 15 | 18.5 |

| Gross Power | kW | 19.5 | 23 |

| Exhausted Water | m3/h | 3 | 4.5 |

| Gross Weight | kg | 3800 | 3600 |

| Overall Dimensions(L*W*H) | mm | 5400*2150*2600 | 5400*2150*2600 |